With the continuous development of science and technology, non-woven fabrics, as a new type of environmentally friendly material, have been widely used in various fields. However, some defects will inevitably occur during the production process of non-woven fabrics, such as pinholes and holes. In order to improve the quality of non-woven fabrics, many companies have begun to use non-woven fabric defect online detectors for real-time monitoring. So, how to use the non-woven defect online detector? What is its detection effect? This article will give you a detailed answer.

1. Basic principles of non-woven fabric defect online detector

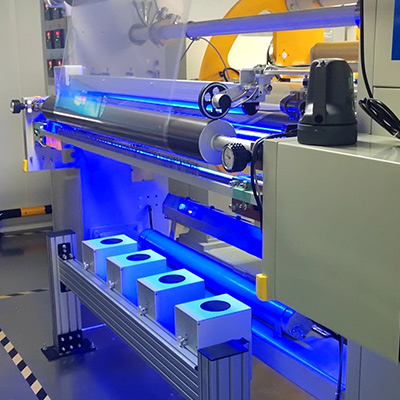

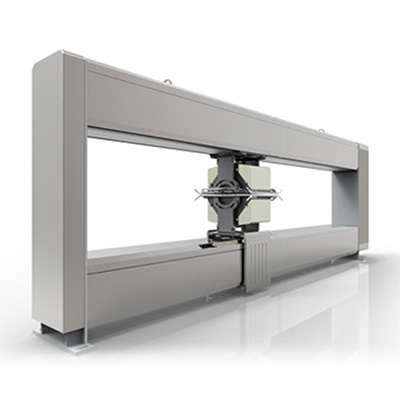

The non-woven defect online detector is a device that uses optical imaging technology to conduct quality inspection on the surface of non-woven fabrics. It takes real-time photos of non-woven fabrics through cameras installed on the production line, and then transmits the images to a computer for processing. The computer analyzes the feature points in the image to identify defects on the surface of the non-woven fabric and outputs corresponding alarm signals. The entire process is automated and intelligent, which greatly improves production efficiency and product quality.

2. How to use the non-woven defect online detector

1. Equipment installation: First, the non-woven defect online detector needs to be installed at a suitable location on the production line to ensure that the camera can cover the area to be inspected. In addition, equipment such as power supply, air source, and data cables need to be connected to ensure the normal operation of the equipment.

2. Equipment debugging: After starting up, the equipment needs to be debugged to a certain extent. First calibrate the parameters of the camera so that it can accurately capture images; then adjust the parameters of the computer software, such as threshold, sensitivity, etc., to obtain the best detection effect.

3. Operation training: After the equipment debugging is completed, the operators need to be trained so that they can master the use methods and precautions of the equipment. Operators should understand the working principle, detection procedures, troubleshooting methods, etc. of the equipment.

4. Routine maintenance: In order to ensure the long-term stable operation of the equipment, the equipment needs to be maintained regularly. Mainly includes cleaning the surface of the equipment, replacing camera filters, checking cable connections, etc. At the same time, the equipment needs to be regularly tested for performance to ensure its detection accuracy and stability.

3. Detection effect of non-woven fabric defect online detector

It has been proved through practical application that the non-woven defect online detector has high detection accuracy and stability. It can monitor the surface quality of non-woven fabrics in real time and effectively find and eliminate defective products, thereby improving the company's product quality and market competitiveness. In addition, the equipment also has the characteristics of easy operation and quick response, saving labor costs and time costs for enterprises. Therefore, the non-woven fabric defect online detector has high practical value in actual production.

The non-woven defect online detector is an effective non-woven quality monitoring tool. It is simple to use and has good detection results. For enterprises, the introduction and application of this equipment can not only improve product quality, but also reduce production costs and improve market competitiveness. Therefore, companies can consider purchasing and using non-woven fabric defect online detectors.

Top

Top

Email

Email

WhatsApp

WhatsApp

Submit Form

Submit Form

Down

Down