Introduction: In the modern manufacturing industry, the quality of film products is of paramount importance. Surface defects can significantly affect the functionality and aesthetics of films used in various applications, ranging from food packaging to electronic components. Consequently, the development and implementation of advanced film surface defect detection systems have become crucial for ensuring high-quality production. This article explores the latest technologies and methodologies in film surface defect detection, highlighting their impact on enhancing quality control in manufacturing processes.

Latest Technologies in Film Surface Defect Detection:

-

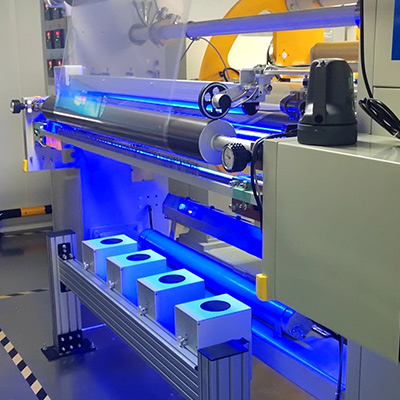

Machine Vision Systems: Machine vision technology has revolutionized the way surface defects are detected in film manufacturing. These systems utilize high-resolution cameras to capture images of the film surface and sophisticated image processing algorithms to analyze and identify defects. Machine vision systems can detect a wide range of defects, including pinholes, bubbles, contamination, and scratches, with high accuracy and speed.

-

Artificial Intelligence and Deep Learning: The integration of artificial intelligence (AI) and deep learning algorithms into film surface defect detection systems has significantly improved their performance. These algorithms enable the system to learn from a vast number of images and identify complex patterns that may indicate surface defects. AI-driven systems can adapt to various types of defects and continuously improve their detection accuracy over time.

-

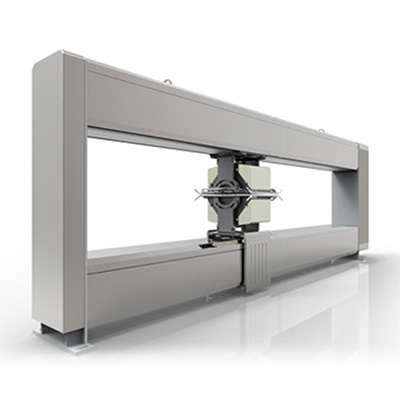

Automated Inspection Systems: Automated inspection systems have replaced manual inspection methods in many manufacturing settings. These systems operate continuously and can inspect large areas of film surfaces at high speeds. By integrating advanced sensors and data analysis tools, automated inspection systems provide real-time feedback on defect presence, location, and severity, allowing for immediate corrective actions.

-

Spectroscopic Techniques: Spectroscopic techniques, such as infrared and ultraviolet spectroscopy, are employed to detect surface defects by analyzing the film’s chemical and physical properties. These methods can identify subtle defects that may not be visible to the naked eye or conventional imaging systems.

Impact on Quality Control:

-

Improved Detection Accuracy: Advanced film surface defect detection systems offer significantly higher accuracy compared to traditional inspection methods. This results in a lower rate of defective products reaching the market, thereby enhancing customer satisfaction and brand reputation.

-

Increased Production Efficiency: The real-time detection and classification of surface defects enable manufacturers to address issues promptly, reducing downtime and improving overall production efficiency. Automated systems also eliminate the subjectivity and fatigue associated with manual inspection.

-

Cost Savings: By identifying defects early in the production process, manufacturers can prevent the production of defective products, reducing material waste and associated costs. Additionally, the use of automated systems reduces labor costs and increases productivity.

Conclusion: The continuous advancements in film surface defect detection technologies have had a profound impact on the manufacturing industry. By improving detection accuracy, increasing production efficiency, and reducing costs, these systems play a vital role in ensuring the production of high-quality film products. As technology evolves, we can expect further innovations in film surface defect detection, leading to even higher standards of quality control in the future.

Top

Top

Email

Email

WhatsApp

WhatsApp

Submit Form

Submit Form

Down

Down