Abstract: The demand for high-quality cold-rolled steel strips is paramount in various industrial sectors. This paper introduces an innovative solution designed to detect and categorize surface defects in cold-rolled steel strips, leveraging the latest technological advancements. The system is tailored to enhance production quality and reduce the rate of defective products.

- Background

Cold-rolled steel strips are widely used in applications that require precise dimensions and surface quality. Surface defects can arise during the production process, affecting the material’s functionality and aesthetics. To ensure the integrity of the final product, it is imperative to implement an effective defect detection system. This paper delves into a novel approach that combines advanced imaging techniques with sophisticated analysis algorithms to identify surface defects.

- System Architecture

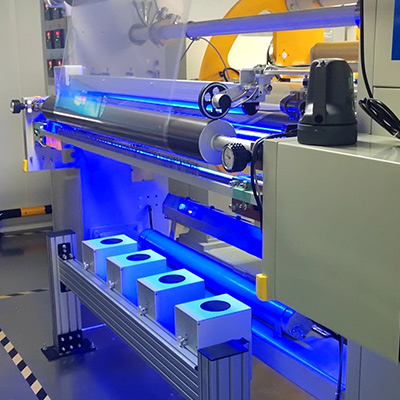

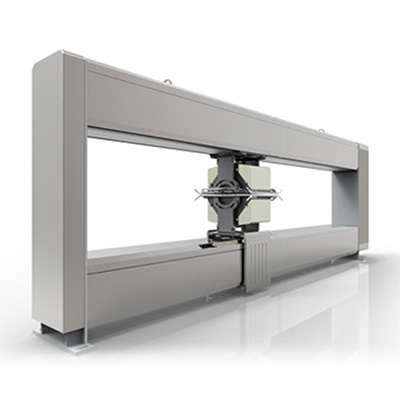

The defect detection system for cold-rolled steel strips is composed of the following components:

- High-definition imaging sensors: Captures detailed images of the steel strips under controlled lighting.

- Advanced lighting system: Ensures consistent and optimal illumination to highlight surface irregularities.

- Image transmission module: Facilitates the transfer of images to the processing unit for analysis.

- Defect analysis module: Employs a suite of algorithms to detect and classify surface defects.

- Interactive dashboard: Provides real-time feedback and allows for system customization.

- Image Analysis Techniques

The defect analysis module incorporates a range of image analysis techniques to ensure accurate defect detection:

- Image preprocessing: Enhances image quality through noise reduction and contrast adjustment.

- Segmentation:分离出缺陷区域,为后续分析做准备。

- Feature extraction: Identifies unique characteristics of defects, such as shape, size, and texture.

- Pattern recognition: Uses extracted features to classify defects into predefined categories.

- Defect Detection Process

The defect detection process is outlined as follows:

- Data collection: Gathers a extensive dataset of steel strip images with annotated defects.

- Algorithm development: Develops and refines algorithms for defect detection based on the collected data.

- Model training: Trains machine learning models, such as deep learning networks, to recognize and categorize defects.

- Performance evaluation: Validates the effectiveness of the models using statistical metrics.

- Deployment: Integrates the trained models into the production line for real-time defect detection.

- Conclusion

The innovative surface defect detection system for cold-rolled steel strips presented in this paper offers a robust and efficient method for ensuring product quality. By combining state-of-the-art imaging, image analysis, and machine learning technologies, the system promises to significantly reduce the occurrence of defective products in the market. Future research will aim to refine the system’s capabilities, enhancing its precision and adaptability to diverse manufacturing environments.

Top

Top

Email

Email

WhatsApp

WhatsApp

Submit Form

Submit Form

Down

Down