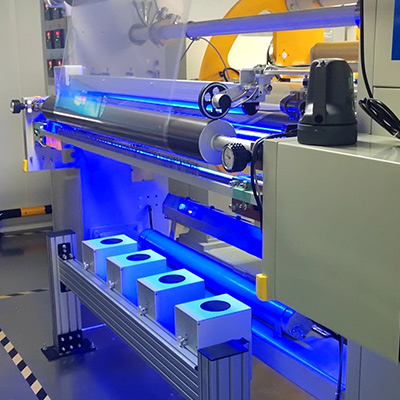

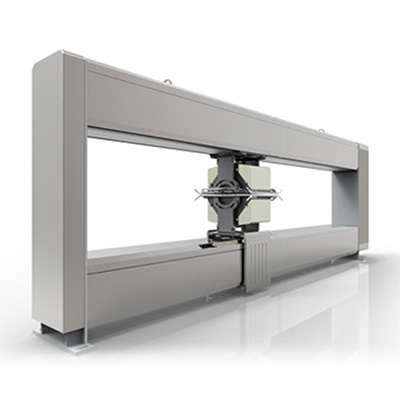

In modern industrial production, precision and efficiency are paramount. One of the key tools that enable manufacturers to achieve these goals is the online thickness gauge. This advanced measurement device is used to monitor and control the thickness of materials in real-time during the production process. Online thickness gauges are widely employed in industries such as metal processing, plastics, paper manufacturing, and glass production. Their ability to provide accurate, continuous, and non-destructive measurements makes them an indispensable component of quality control systems. This article explores the advantages, working principles, and applications of online thickness gauges.

1. Real-Time Monitoring and Control

One of the most significant advantages of online thickness gauges is their ability to provide real-time measurements. Unlike traditional methods that require manual sampling and offline analysis, online gauges continuously monitor the thickness of materials as they move through the production line. This allows for immediate detection of deviations from the desired thickness, enabling operators to make quick adjustments to the process. Real-time monitoring ensures consistent product quality and reduces the risk of producing out-of-specification materials.

2. High Accuracy and Precision

Online thickness gauges are designed to deliver highly accurate and precise measurements. They utilize advanced sensing technologies, such as laser, ultrasonic, or X-ray, to measure thickness with micron-level accuracy. This level of precision is critical in industries where even minor variations in thickness can affect the performance, safety, or aesthetics of the final product. For example, in the production of metal sheets for automotive applications, precise thickness control is essential to ensure the strength and durability of the components.

3. Non-Destructive Testing

Online thickness gauges perform non-destructive testing, meaning they do not damage or alter the material being measured. This is a significant advantage over traditional methods that may require cutting or sampling the material, leading to waste and additional processing time. Non-destructive testing ensures that the entire production batch can be inspected without compromising the integrity of the product.

4. Improved Efficiency and Productivity

By integrating online thickness gauges into the production process, manufacturers can significantly improve efficiency and productivity. These devices eliminate the need for manual measurements and reduce the frequency of production stoppages for quality checks. As a result, production lines can operate at higher speeds with minimal interruptions, leading to increased output and reduced downtime. Additionally, the automation of thickness measurement reduces the reliance on human operators, minimizing the risk of errors and inconsistencies.

5. Cost Savings

Online thickness gauges contribute to cost savings in several ways. First, they reduce material waste by ensuring that thickness variations are detected and corrected early in the production process. Second, they lower labor costs by automating the measurement process and reducing the need for manual inspections. Third, they help prevent the production of defective products, which can lead to costly rework, scrap, or customer returns. Over time, these savings can offset the initial investment in the equipment, making online thickness gauges a cost-effective solution for quality control.

6. Versatility Across Materials and Industries

Online thickness gauges are highly versatile and can be used to measure a wide range of materials, including metals, plastics, paper, glass, and coatings. This versatility makes them suitable for various industries, such as:

-

Metal Processing: Monitoring the thickness of rolled steel, aluminum, or copper sheets.

-

Plastics: Ensuring uniform thickness in extruded plastic films or molded parts.

-

Paper Manufacturing: Controlling the thickness of paper or cardboard during production.

-

Glass Production: Measuring the thickness of glass panels or bottles.

-

Coatings: Verifying the thickness of paint, adhesive, or protective coatings on surfaces.

7. Data Logging and Analysis

Modern online thickness gauges are equipped with data logging and analysis capabilities. They can store measurement data over time, allowing manufacturers to track trends, identify patterns, and analyze process performance. This data can be used to optimize production parameters, improve process control, and ensure compliance with industry standards. Additionally, the integration of online thickness gauges with factory automation systems enables seamless data sharing and centralized monitoring.

8. Enhanced Safety

In industries where material thickness is critical to safety, such as aerospace or construction, online thickness gauges play a vital role. For example, in the production of aircraft components, precise thickness control is essential to ensure the structural integrity and safety of the parts. By providing real-time feedback, online thickness gauges help prevent the production of substandard materials that could compromise safety.

9. Compliance with Industry Standards

Many industries are subject to strict regulatory requirements regarding material thickness. Online thickness gauges help manufacturers comply with these standards by providing accurate and documented measurements. This not only ensures compliance but also simplifies audits and certifications, as the data generated by the gauges can serve as proof of adherence to quality guidelines.

Online thickness gauges are a powerful tool for modern manufacturing, offering numerous advantages such as real-time monitoring, high accuracy, non-destructive testing, and cost savings. Their versatility and ability to integrate with production processes make them suitable for a wide range of industries and applications. By investing in online thickness gauges, manufacturers can enhance product quality, improve efficiency, and maintain a competitive edge in the market. As technology continues to advance, these devices will play an increasingly important role in ensuring precision and consistency in industrial production.

Top

Top

Email

Email

WhatsApp

WhatsApp

Submit Form

Submit Form

Down

Down