Thin films are critical components in a variety of industries, including electronics, packaging, and solar energy. The quality of these films is paramount, as even minor defects can compromise their functionality and performance. Traditional methods of defect detection, often reliant on manual inspection, are increasingly inadequate for modern high-speed production lines. This has led to the development and adoption of online defect detection systems, which utilize advanced technologies to ensure the integrity and quality of thin films during the manufacturing process.

The Importance of Defect Detection in Thin Films

Defects in thin films can manifest as pinholes, scratches, thickness variations, or inclusions. These imperfections can adversely affect the film's mechanical, electrical, or optical properties. For instance, in the electronics industry, defects in thin films used for semiconductor devices can lead to circuit failures. In the packaging industry, defects can compromise the barrier properties of the film, leading to product spoilage. Therefore, detecting and addressing these defects in real-time is crucial for maintaining product quality and performance.

Traditional vs. Online Defect Detection Methods

Historically, defect detection in thin films has been performed offline, using manual inspection or laboratory-based techniques. These methods are not only time-consuming but also prone to human error and cannot keep up with the high-speed production rates of modern manufacturing lines.

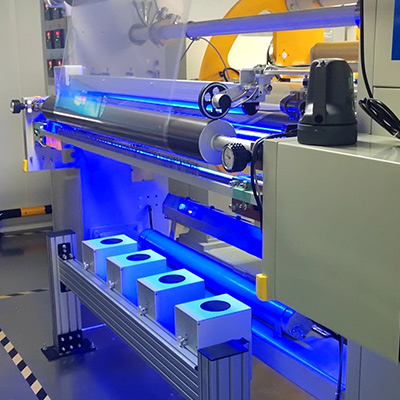

Online defect detection systems, on the other hand, offer a more efficient and reliable solution. These systems are integrated directly into the production line, allowing for continuous monitoring and immediate feedback. By leveraging advanced technologies such as machine vision, artificial intelligence (AI), and sophisticated sensors, online systems can detect defects with high accuracy and speed.

Technologies in Online Defect Detection

-

Machine Vision Systems: Machine vision is the cornerstone of online defect detection. High-resolution cameras and specialized lighting systems capture detailed images of the thin film as it moves through the production line. These images are then analyzed in real-time using advanced algorithms to identify and classify defects. The system can be trained to recognize various types of defects, ensuring a high level of accuracy.

-

Artificial Intelligence and Machine Learning: AI and machine learning algorithms enhance the capabilities of machine vision systems. By learning from vast datasets of defect images, these algorithms can improve their detection accuracy over time. They can also adapt to new types of defects, making the system more versatile and future-proof.

-

Laser Scanning and Profilometry: Laser scanning systems use laser beams to measure the surface profile and thickness of the thin film. Any deviations from the specified parameters can be identified as defects. This method is highly accurate and suitable for detecting subtle variations that might be missed by other techniques.

-

Spectral Imaging: Spectral imaging involves capturing images at multiple wavelengths, providing more detailed information about the film's surface. This technique is particularly useful for detecting defects that are not visible to the naked eye or standard cameras, such as variations in material composition.

Benefits of Online Defect Detection

The implementation of online defect detection systems offers numerous benefits to manufacturers:

-

Real-Time Monitoring: Continuous monitoring allows for immediate detection and correction of defects, minimizing the production of defective material.

-

Increased Accuracy: Automated systems are capable of detecting defects with a level of precision that surpasses human capability.

-

Enhanced Productivity: Real-time detection allows for immediate corrective actions, minimizing downtime and maximizing production efficiency.

-

Cost Savings: By reducing the number of defective products, manufacturers can save on material costs and avoid costly recalls or reputational damage.

-

Consistency: Automated systems provide consistent inspection quality, unaffected by human factors such as fatigue or subjective judgment.

Challenges and Future Directions

Despite the advantages, there are challenges associated with online defect detection in thin films. The variability in film types and defect characteristics requires robust and adaptable systems. Additionally, the initial investment in advanced detection technologies can be significant, though the long-term benefits often justify the cost.

Looking ahead, the integration of Internet of Things (IoT) technologies and further advancements in AI are expected to enhance the capabilities of defect detection systems. IoT can enable better data collection and analysis across the production line, while AI can lead to even more sophisticated defect recognition and predictive maintenance capabilities.

Online defect detection is revolutionizing the thin film industry by ensuring high-quality production standards and enhancing operational efficiency. As technologies continue to evolve, these systems will become even more integral to the manufacturing process, helping manufacturers meet the ever-increasing demands for quality and performance in thin films.

Top

Top

Email

Email

WhatsApp

WhatsApp

Submit Form

Submit Form

Down

Down