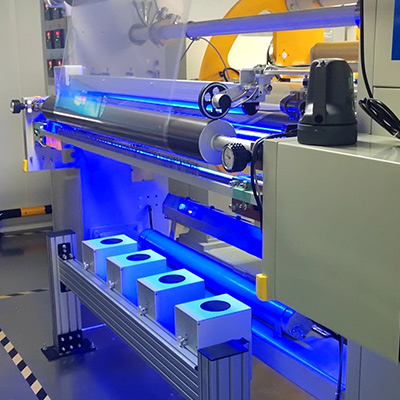

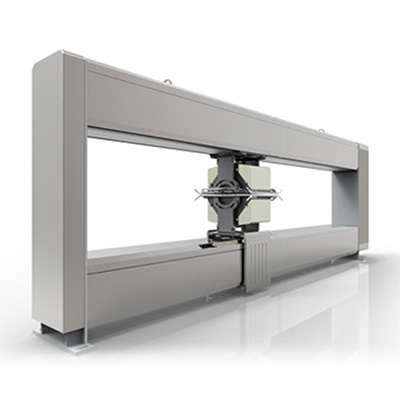

In industries ranging from electronics and solar panels to packaging and automotive manufacturing, the demand for flawless thin-film materials has never been higher. A Film Defect Inspection System is a cutting-edge solution designed to detect microscopic imperfections such as scratches, pinholes, bubbles, contamination, or coating irregularities on film surfaces. By integrating advanced optical imaging, artificial intelligence (AI), and automation, these systems ensure superior product quality while optimizing production efficiency.

How It Works

-

High-Resolution Imaging: Utilizing high-speed cameras, hyperspectral imaging, or laser scanning, the system captures detailed surface data of films in real time.

-

AI-Driven Analysis: Deep learning algorithms, trained on vast defect databases, classify and quantify defects with sub-micron precision.

-

Real-Time Feedback: Detected defects are flagged instantly, enabling immediate corrective actions or automated rejection of faulty products.

-

Multi-Layer Inspection: For laminated films, the system can analyze individual layers to identify interlayer defects.

Key Technologies

-

Machine Vision: Combines line-scan cameras and structured lighting to handle high-speed production lines.

-

Defect Classification AI: Convolutional neural networks (CNNs) distinguish critical defects from harmless artifacts.

-

Multi-Spectral Imaging: Detects defects invisible to the naked eye, such as UV-sensitive coating flaws.

-

Cloud Integration: Stores defect patterns for trend analysis and process optimization.

Applications

-

Flexible Electronics: Ensures defect-free displays, touchscreens, and printed circuits.

-

Photovoltaic Films: Identifies micro-cracks in solar panels to enhance energy efficiency.

-

Packaging Films: Guarantees barrier integrity for food, medical, and industrial packaging.

-

Automotive Films: Screens coatings for windows, headlights, and interior components.

Advantages Over Traditional Methods

-

Non-Contact Inspection: Eliminates damage risks to delicate films.

-

100% Inspection Coverage: Replaces error-prone manual sampling.

-

Adaptability: Handles transparent, reflective, or textured films.

-

Cost Savings: Reduces material waste and recalls by up to 90%.

By merging precision optics with AI intelligence, film defect inspection systems redefine quality assurance standards, empowering manufacturers to deliver flawless products in an era where perfection is non-negotiable.

Top

Top

Email

Email

WhatsApp

WhatsApp

Submit Form

Submit Form

Down

Down