Metal surface defect detection is a critical quality control process in manufacturing industries such as automotive, aerospace, and construction. Imperfections like cracks, scratches, dents, or corrosion can compromise structural integrity, safety, and aesthetics. Traditional manual inspection methods are labor-intensive, time-consuming, and prone to human error. To address these limitations, automated detection systems leveraging advanced imaging, machine learning (ML), and computer vision have emerged as transformative solutions. This article explores the evolution of defect detection technologies, current methodologies, and future directions.

Traditional Approaches to Defect Detection

1. Visual Inspection

Manual inspection by trained technicians has been the industry standard for decades. However, its subjectivity, fatigue-related errors, and inefficiency in high-volume production lines have driven the demand for automation.

2. Computer Vision Techniques

Early automated systems relied on classical image processing algorithms:

-

Edge Detection: Algorithms like Canny or Sobel operators identify abrupt intensity changes to locate defects.

-

Thresholding: Segmentation based on pixel intensity to isolate anomalies.

-

Morphological Operations: Techniques like erosion/dilation to enhance defect features.

-

Filtering: Noise reduction using Gaussian or median filters.

While effective for simple defects, these methods struggle with complex patterns, varying lighting conditions, and subtle imperfections.

Machine Learning and Deep Learning Revolution

1. Feature-Based Machine Learning

Early ML approaches combined handcrafted features (e.g., texture, shape, or color descriptors) with classifiers like SVM or Random Forests. For example:

-

Local Binary Patterns (LBP) for texture analysis.

-

Haralick Features for surface roughness quantification.

Limitations: Feature engineering is laborious and may miss latent patterns in heterogeneous defect types.

2. Deep Learning (DL) Approaches

Convolutional Neural Networks (CNNs) have revolutionized defect detection by automating feature extraction. Key architectures include:

a. Classification Models

-

CNN Backbones: Pre-trained networks like ResNet, VGG, or EfficientNet classify defects using labeled datasets.

-

Transfer Learning: Fine-tuning models on small industrial datasets to reduce training time.

b. Object Detection Frameworks

-

Faster R-CNN and YOLO (You Only Look Once): Detect and localize defects in real-time.

-

Single-Shot Detectors (SSD): Balance speed and accuracy for high-throughput systems.

c. Semantic Segmentation

-

U-Net and Mask R-CNN: Pixel-wise defect mapping for precise boundary identification, critical for quantifying damage.

3. Data Augmentation and Synthesis

-

Generative Adversarial Networks (GANs): Generate synthetic defect data to overcome limited training samples.

-

Style Transfer: Adapt models to diverse lighting or surface textures.

Challenges in Metal Defect Detection

1. Data Scarcity and Imbalance

-

Annotating industrial datasets is costly and time-consuming.

-

Rare defects (e.g., micro-cracks) lead to class imbalance, biasing models.

2. Complex Defect Morphology

-

Variations in defect size, shape, and orientation (e.g., elongated cracks vs. circular pits).

-

Overlapping defects or ambiguous boundaries.

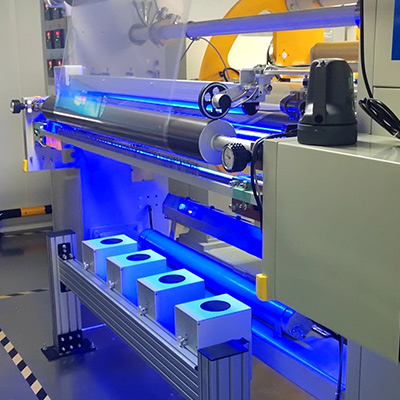

3. Real-Time Processing

-

High-resolution imaging (e.g., 4K cameras) demands efficient algorithms for inline inspection.

4. Environmental Factors

-

Reflections, shadows, or dust on metal surfaces create false positives.

-

Inconsistent lighting in industrial settings.

Emerging Trends and Innovations

1. Lightweight Models for Edge Computing

-

Deploying compact architectures like MobileNet or SqueezeNet on embedded systems (e.g., NVIDIA Jetson) reduces latency and hardware costs.

2. Multimodal Data Fusion

-

Combining visual data with thermal imaging, ultrasonic testing, or laser scanning improves robustness.

3. Self-Supervised Learning

-

Models like Vision Transformers (ViTs) learn representations from unlabeled data, reducing annotation dependency.

4. Explainable AI (XAI)

-

Tools like Grad-CAM or SHAP enhance transparency by highlighting defect regions influencing model decisions.

5. Digital Twin Integration

-

Simulating production lines with digital twins enables predictive maintenance and defect root-cause analysis.

Case Studies

1. Steel Manufacturing

-

Challenge: Detecting rolling defects (e.g., seams or scale marks) in hot-rolled steel strips.

-

Solution: A hybrid CNN-SVM system achieves 98.5% accuracy by analyzing surface texture and thermal profiles.

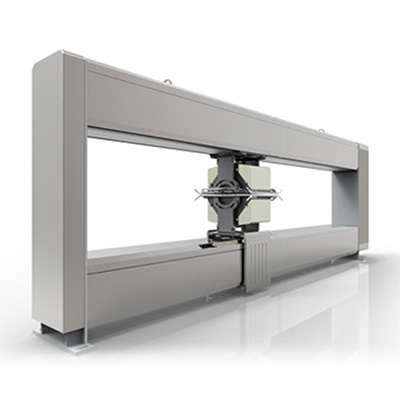

2. Automotive Industry

-

Application: Inspecting welded joints in car bodies using laser triangulation and 3D point cloud analysis.

3. Aerospace Components

-

Innovation: X-ray tomography combined with DL identifies subsurface defects in turbine blades.

Conclusion

Automated metal surface defect detection is pivotal for advancing Industry 4.0 and smart manufacturing. While deep learning has significantly improved accuracy, challenges like real-time deployment, data scarcity, and environmental variability persist. Future advancements in multimodal sensing, edge AI, and self-supervised learning promise to bridge these gaps, enabling faster, safer, and more cost-effective quality assurance systems.

This article provides a comprehensive overview while highlighting technical depth. Let me know if you'd like to expand on specific sections or add more examples!

Top

Top

Email

Email

WhatsApp

WhatsApp

Submit Form

Submit Form

Down

Down