Cables are vital components in power transmission, telecommunications, automotive systems, and industrial machinery. Surface defects such as scratches, cracks, dents, or uneven coatings can compromise electrical conductivity, insulation integrity, and long-term durability. Automated defect detection systems are essential to ensure safety, compliance, and operational efficiency across industries.

Technologies for Cable Defect Detection

-

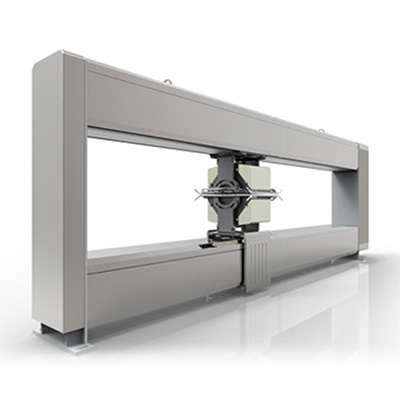

3D Laser Scanning:

-

Captures high-resolution 3D profiles of cylindrical cable surfaces, identifying micro-scale deformations or protrusions.

-

Ideal for detecting dents, bulges, or coating irregularities in real time.

-

-

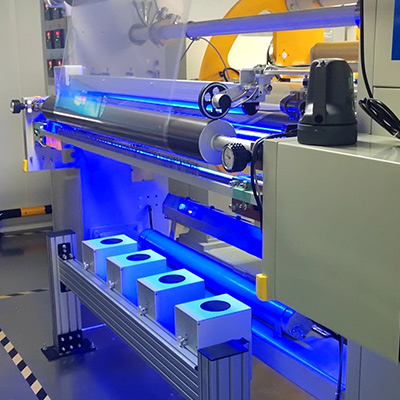

Multi-Angle Optical Imaging:

-

Uses synchronized cameras with ring-shaped LED lighting to eliminate shadows and glare on curved surfaces.

-

Detects scratches, discoloration, or contamination across diverse cable colors and textures.

-

-

Hyperspectral Imaging:

-

Analyzes material composition to spot impurities or degraded insulation layers (e.g., oxidized polymers).

-

-

AI-Powered Defect Classification:

-

Deep learning models (e.g., YOLO or U-Net architectures) segment defects, classify severity, and trigger automated rejection systems.

-

Key Challenges

-

Complex Geometry: Cylindrical shapes and flexible cables require dynamic inspection setups to avoid blind spots.

-

High-Speed Production: Inspection must synchronize with extrusion or winding processes exceeding 100 meters/minute.

-

Material Variability: Glossy, matte, or textured surfaces demand adaptable lighting and algorithms.

-

Environmental Noise: Dust, vibrations, or ambient light in industrial settings can interfere with accuracy.

Industrial Applications

-

Power Cables: Detecting insulation flaws prevents electrical leaks, fires, or outages in energy grids.

-

Automotive Wiring Harnesses: Ensures defect-free connections to avoid short circuits in vehicles.

-

Fiber Optic Cables: Identifies micro-cracks that disrupt signal transmission in telecom networks.

-

Industrial Robotics: Maintains reliability of cables used in robotic arms exposed to mechanical stress.

Emerging Trends

-

Edge AI: Lightweight neural networks deployed on embedded devices reduce latency for real-time decision-making.

-

Digital Twins: Simulates cable production lines to predict defect hotspots and optimize inspection parameters.

-

IoT Integration: Combines defect data with predictive maintenance systems to extend cable lifespan.

Advanced cable surface defect detection systems merge precision imaging, adaptive algorithms, and industrial automation to address growing demands for quality and safety. By minimizing human error and enabling 100% inline inspection, these technologies reduce waste, lower recall risks, and uphold compliance with standards like IEC 60228 or UL 62. As industries adopt smarter manufacturing practices, robust defect detection will remain a cornerstone of cable production, ensuring reliability in an increasingly connected world.

This article highlights the technical advancements and practical implications of cable defect detection. Let me know if you’d like to explore specific use cases or technical details further!

Top

Top

Email

Email

WhatsApp

WhatsApp

Submit Form

Submit Form

Down

Down