Steel is everywhere—in cars, bridges, buildings, and machines. But even the toughest steel can have tiny flaws like cracks, rust spots, dents, or scratches. These defects might seem small, but they can weaken the metal and cause big problems later. That’s why steel surface defect detection is so important!

How Does It Work?

-

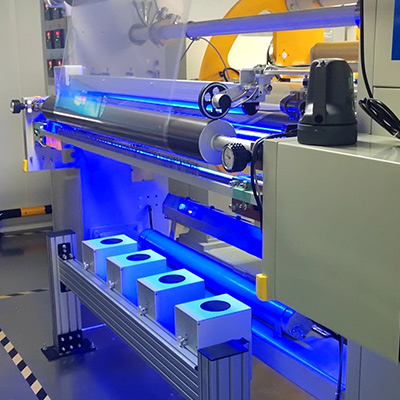

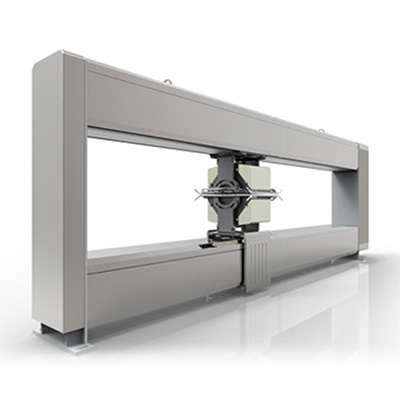

Snap a Picture: Special cameras or sensors scan the steel surface as it moves through a factory.

-

Spot the Flaws: Smart software (like a detective) checks the images for defects. It’s trained to recognize cracks, rust, or uneven textures.

-

Sound the Alarm: If a flaw is found, the system alerts workers or even automatically marks the bad steel for repair or recycling.

Why Is This Better Than Old Methods?

-

No More Guesswork: Humans can miss tiny flaws, especially on fast-moving production lines. Machines don’t get tired!

-

Super Fast: It checks every inch of steel in seconds, keeping factories running smoothly.

-

Saves Money: Catching defects early means less wasted material and fewer broken products.

Where Is It Used?

-

Car Factories: Ensures car frames and parts are flawless.

-

Construction: Checks steel beams for bridges or skyscrapers.

-

Shipbuilding: Finds hidden rust or cracks in huge metal plates.

Cool Tech Behind It

-

AI and Machine Learning: The system learns from thousands of steel images to get smarter over time.

-

Laser Scanners: These can “see” even the tiniest scratches.

-

Robotic Arms: Some systems fix small defects automatically!

Steel surface defect detection is like a superhero for metal—it spots hidden dangers, keeps people safe, and makes sure the steel we use every day is strong and reliable. Thanks to technology, our buildings, cars, and gadgets are built to last!

Top

Top

Email

Email

WhatsApp

WhatsApp

Submit Form

Submit Form

Down

Down