Surface defect detection in steel strip metal is a critical quality control process in the manufacturing industry. Defects such as scratches, cracks, pits, and rust can compromise the structural integrity, aesthetics, and performance of steel products. Traditional manual inspection methods are time-consuming, subjective, and prone to human error. As industries demand higher precision and efficiency, automated defect detection systems have emerged as essential tools. This article explores the current techniques, challenges, and technological advancements in surface defect detection for steel strips.

Traditional Methods for Surface Defect Detection

-

Visual Inspection:

Human inspectors use magnifying tools or microscopes to identify defects. While simple, this method is labor-intensive and inconsistent, especially for high-speed production lines. -

Eddy Current Testing:

Electromagnetic techniques detect surface cracks by measuring changes in conductivity. However, they struggle with non-conductive coatings and complex geometries. -

Laser Scanning:

Laser profilometry creates 3D surface maps to identify irregularities. Though accurate, it is expensive and sensitive to environmental vibrations. -

Image Processing with Traditional Algorithms:

Early automated systems used edge detection (e.g., Sobel, Canny filters) and texture analysis (e.g., Gabor filters) to highlight defects. These methods often failed under variable lighting or complex backgrounds.

Challenges in Modern Steel Defect Detection

-

High-Speed Production Lines:

Modern steel mills operate at speeds exceeding 20 m/s, requiring real-time detection with millisecond-level responses. -

Complex Background Noise:

Steel surfaces exhibit textures, reflections, and oil residues that mimic defects, leading to false positives. -

Defect Variability:

Defects vary in size, shape, and contrast. Micro-defects (e.g., pinholes < 0.1 mm) are particularly challenging to detect. -

Harsh Industrial Environments:

Dust, temperature fluctuations, and mechanical vibrations interfere with sensor accuracy.

Deep Learning-Based Solutions

Recent advances in artificial intelligence (AI) and computer vision have revolutionized defect detection. Key approaches include:

-

Convolutional Neural Networks (CNNs):

CNNs automatically learn hierarchical features from images, outperforming traditional algorithms in accuracy. Popular architectures include:-

Faster R-CNN: A two-stage detector for high-precision localization.

-

YOLO (You Only Look Once): A single-stage detector optimized for real-time processing.

-

U-Net: A segmentation network for pixel-level defect mapping.

-

-

Data Augmentation and Synthetic Defects:

Limited defect datasets are expanded using techniques like rotation, noise injection, and generative adversarial networks (GANs) to simulate rare defects. -

Transfer Learning:

Pre-trained models (e.g., ResNet, VGG) are fine-tuned on steel defect datasets, reducing training time and data requirements. -

Multimodal Fusion:

Combining data from RGB cameras, infrared sensors, and laser scanners improves robustness. For example, thermal imaging can detect subsurface defects invisible to optical cameras. -

Edge Computing:

Deploying lightweight models (e.g., MobileNet, EfficientNet) on edge devices minimizes latency and enables decentralized processing.

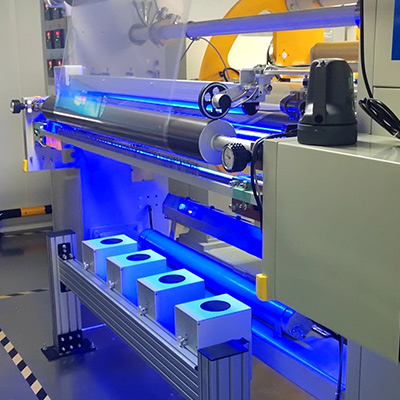

Case Study: Industrial Implementation

A leading steel manufacturer implemented a YOLOv5-based system integrated with high-resolution line-scan cameras. The results included:

-

Detection Accuracy: 99.2% on common defects (scratches, dents).

-

Speed: 200 frames per second, compatible with 15 m/s production lines.

-

Cost Savings: Reduced scrap rate by 30% and inspection labor costs by 70%.

Future Trends

-

Self-Supervised Learning:

Reducing reliance on labeled data by training models on unannotated images. -

Explainable AI (XAI):

Providing visual explanations for defect classifications to build trust among operators. -

IoT Integration:

Linking detection systems with predictive maintenance platforms to forecast equipment failures. -

Quantum Computing:

Accelerating defect recognition algorithms for ultra-high-speed applications.

Automated surface defect detection is pivotal for maintaining quality in steel production. While deep learning has addressed many historical challenges, ongoing research aims to enhance speed, adaptability, and interpretability. As industries embrace Industry 4.0, the fusion of AI, advanced sensors, and edge computing will drive the next generation of intelligent inspection systems, ensuring steel products meet ever-increasing global standards.

Top

Top

Email

Email

WhatsApp

WhatsApp

Submit Form

Submit Form

Down

Down