Aluminum foil is a critical material in industries such as packaging, electronics, and energy storage (e.g., lithium-ion batteries), where surface quality directly impacts performance and safety. Surface defects—including pinholes, scratches, dents, and contaminants—can compromise structural integrity, barrier properties, or conductivity. Detecting these flaws requires advanced inspection systems combining high-resolution imaging, AI-driven analysis, and real-time processing.

Technologies in Defect Detection

-

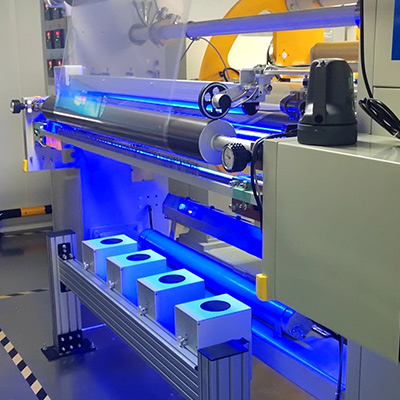

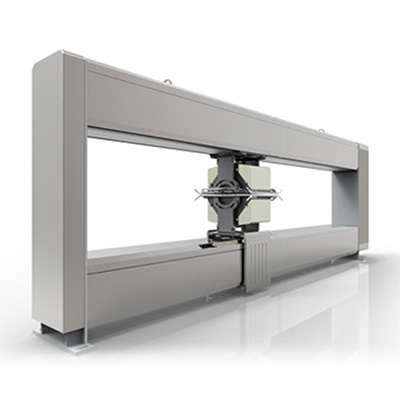

Optical Imaging Systems: High-speed cameras with specialized lighting (e.g., bright-field, dark-field, or coaxial illumination) capture microscopic irregularities on reflective foil surfaces.

-

Machine Vision Algorithms: Edge detection, pattern matching, and deep learning models (e.g., CNNs) classify defects by type, size, and location.

-

Multi-Spectral Analysis: Infrared or ultraviolet imaging identifies contaminants or oxidation invisible to the naked eye.

Challenges

-

Reflectivity: Aluminum’s glossy surface causes glare, requiring adaptive lighting solutions.

-

Speed: High-speed production lines demand millisecond-level detection to avoid bottlenecks.

-

Microscopic Defects: Sub-micron flaws (e.g., pinholes in battery foil) necessitate sub-pixel accuracy.

Industrial Applications

Automated inspection systems enable 100% inline quality control, reducing waste and ensuring compliance with standards like ISO 9001. In battery manufacturing, defect-free foil is vital to prevent short circuits; in food packaging, it ensures hygiene and longevity.

Future Trends

Integration with IoT and predictive maintenance tools will enhance defect prevention, while lightweight AI models optimize edge computing for real-time analytics.

By advancing defect detection technologies, industries achieve higher yields, lower costs, and safer end products, reinforcing aluminum foil’s role in modern manufacturing.

This article outlines the technical framework, industry needs, and innovations driving precision in aluminum foil quality assurance. Let me know if you’d like to expand on specific sections!

Top

Top

Email

Email

WhatsApp

WhatsApp

Submit Form

Submit Form

Down

Down